If you’re in the oil and gas industry, you’re very well aware that your fleet is not just a means of transporting your products or personnel. In fact, for some companies, field and gas activities that heavily rely on fleet vehicles account for up to 80% of their total revenue. As a mission-critical aspect of an oil and gas company’s day-to-day operations, fleet management improvement is a vital aspect of business success.

Fortunately, fleet management technology has drastically improved over the years, giving fleet managers access to invaluable tools for taking their businesses to the next level. One such fleet management innovation is telematics. For a number of industries, the use of telematics has improved safety, reduced fuel consumption, and minimized vehicle breakdowns, just to name a few benefits.

While oil and gas fleets have unique needs and challenges compared to other fleets, the features of today’s advanced telematics solutions offer them many similar benefits.

Here are 3 ways telematics can help improve your oil and gas fleet management.

- Foster Safe Driving Behaviors

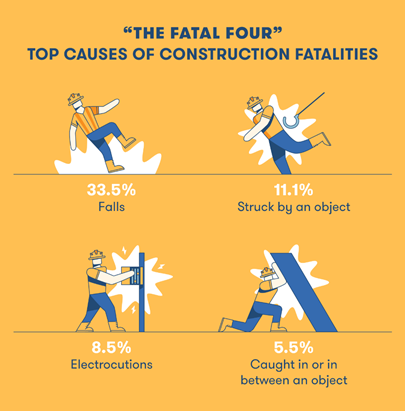

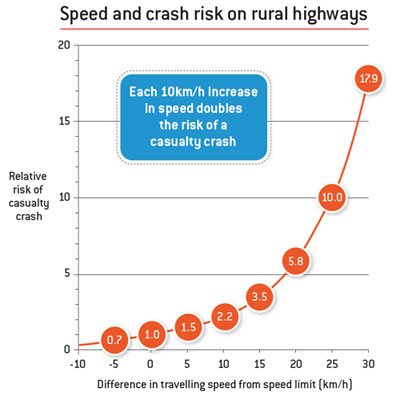

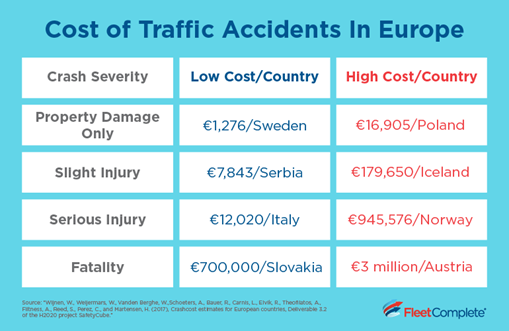

Transporting flammable products such as oil and gas already comes with safety hazards. Unfortunately, these inherent dangers are compounded by the safety risks fleet drivers in the oil and gas sector face on the road. The CDC reports that motor vehicle crashes account for more than 40% of work-related deaths for oil and gas workers

In a 2014 National Institute for Occupational Safety and Health report, it was revealed that driver behaviors such as failing to wear a seatbelt are the leading cause of these fatal accidents—at least 38% of those killed in these crashes were found not wearing seatbelts.

Risky driver behaviors, such as improper use of seatbelts are the leading cause of fatal accidents among oil and gas fleets (Image Source).

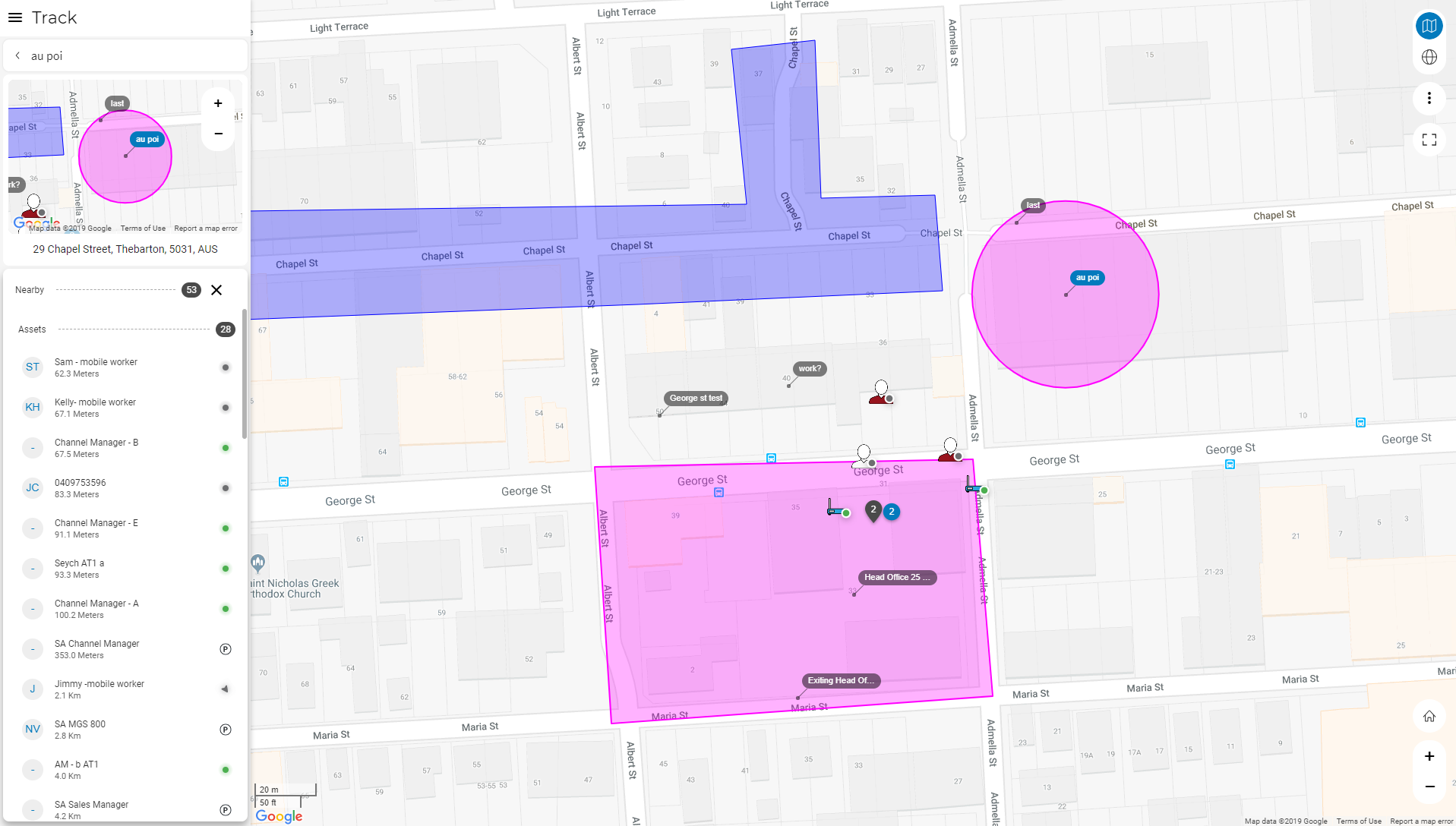

With telematics, fleet managers are given eyes and ears inside their fleet vehicles, allowing them to detect and correct unsafe driving behaviors among their teams. Aside from addressing risky driving behaviors, telematics can also notify fleet managers when drivers are logging more hours than they should. Since driver fatigue is a big contributor to accidents, having access to this information is important for safety management.

Additional features can also improve safety not just on the road, but on a well site too. For instance, Fleet Complete’s safety management solutions give capability to our drivers to switch off the radio frequency of cellular devices upon their arrival at a well site, which reduces potential interference with the other equipment. Data recording continues and transmission will resume once the radio frequency is switched back on.

- Reduce Breakdown of Valuable Assets

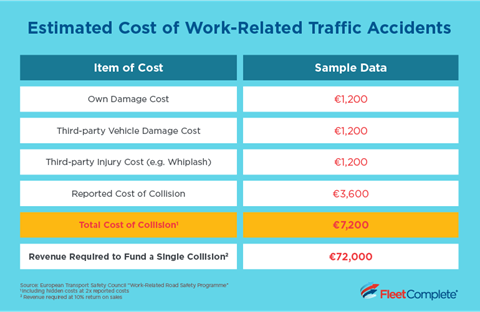

To say that vehicle repairs are costly is an understatement. The cost increases with unplanned roadside repairs. According to the American Trucking Associations’ Technology & Maintenance Council, the average cost of a roadside repair in the fourth quarter of 2019 was $450, a 26% increase compared to the same quarter of 2018. This does not include the cost of towing, which now averages $1,485 per incident.

For oil and gas companies, unscheduled repairs could create a profit leak. As explained by GE Oil & Gas, “Globally, workers lack the tools to see critical data to understand their assets: the history of the asset, the strategy to manage the asset, the impact should the asset fail, or even the current asset health. This lack of information creates a significant risk to safety and profitability.”

Telematics can bridge this information gap, serving as an early diagnostics tool warning fleet managers of possible vehicle breakdowns and heavy machinery failures before they happen.

In this way, telematics not only helps minimize the expenses associated with repairs, but also the costs associated with downtime.

- Reduce Fuel Costs and Improve Fuel Tax Claims

It may sound ironic that oil and gas companies should be concerned about fuel costs, but not taking this expense seriously is an unwise business decision.

According to The Truckers Report, diesel fuel accounts for the biggest chunk of the total operating cost of commercial trucking fleets. One commercial truck can easily consume $70,000 worth of diesel annually. While oil and gas companies supply fuel to commercial fleets in other industries, it doesn’t exempt them from incurring the same expenses.

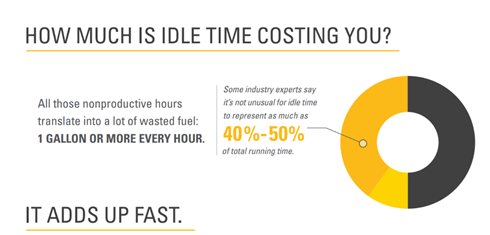

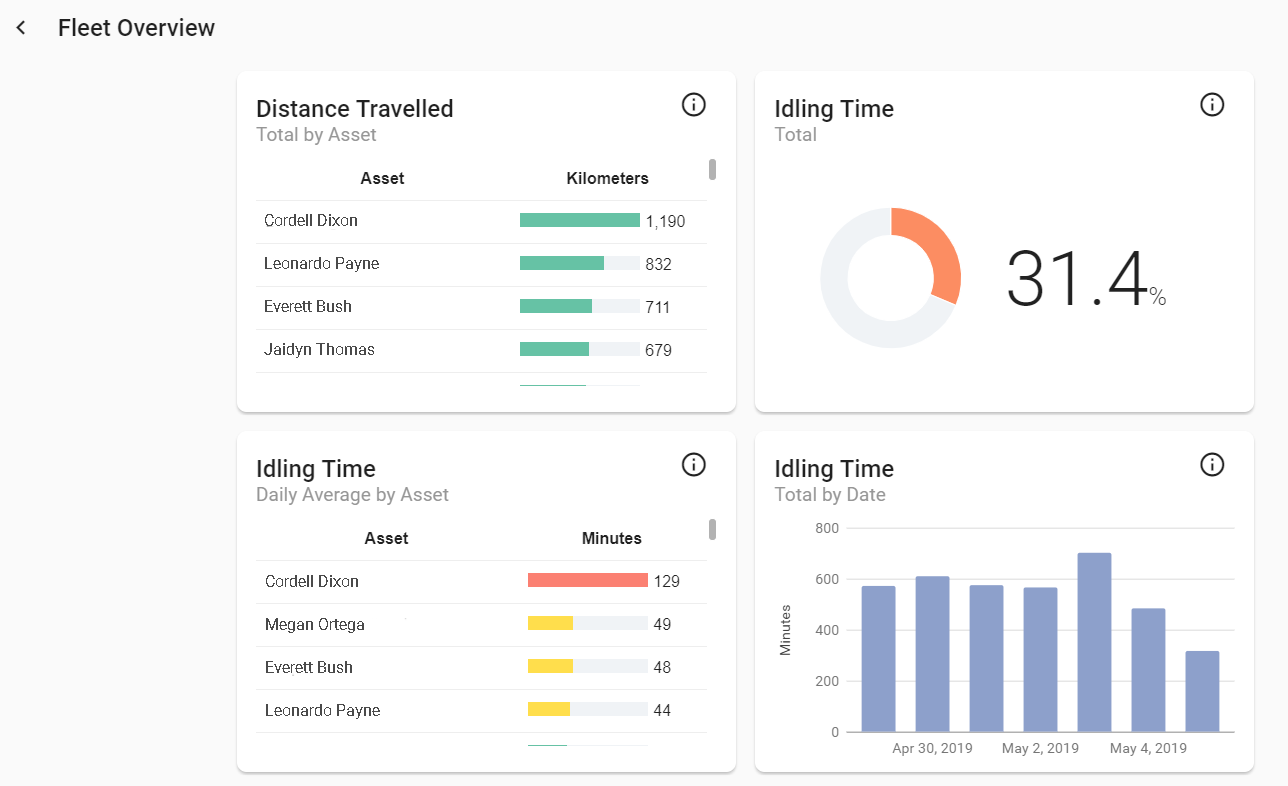

Correcting fuel wasting driver behaviors is, therefore, one of a fleet’s best bets for increasing profitability. For instance, idling has been documented to waste a significant amount of fuel with long haul trucks, wasting approximately 1,500 gallons of diesel per year. Telematics alerts fleet managers of excessive idling so they can immediately correct the problem.

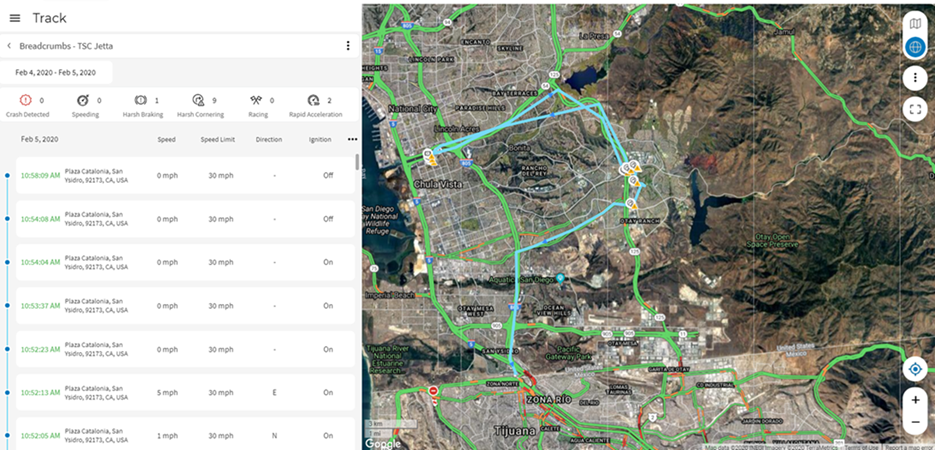

Speaking of fuel savings, another way oil and gas companies can save using telematics is by bolstering their fuel tax claims. With a significant percentage of an oil and gas fleet’s time spent on private roads, oil and gas companies should be eligible for a fuel tax rebate. Not to mention the fuel spent on machinery used on well sites. However, collecting the information to qualify for these tax credits can be time-consuming and burdensome.

Telematics automates this process. With GPS tracking, oil and gas companies can accurately record mileage and, with a trip replay feature, how much fuel is spent on highways and how much is spent on private roads or on-site.

Telematics: Fueling Better Fleet Management in the Oil and Gas Industry

Due to their direct impact on a company’s profitability, extensive monitoring needs to be implemented to track oil and gas fleets to ensure the best utilization of assets. With powerful data collection capabilities, telematics has evolved beyond simply tracking locations. It allows oil and gas companies to get the most out of their fleets while lowering operating costs and making fleet management easier and more effective.